The oil and gas industry is highly demanding, necessitating precision, adaptability, and efficiency to thrive. Complex supply chains, changing market conditions, and regulatory requirements make it increasingly challenging for firms. As a result, ERP software has become one major differentiator in helping them address such challenges in the oil and gas industry.

ERP systems integrate various processes and data across departments and provide real-time insights to facilitate informed and fast decision-making. The tools ensure the optimal utilization of resources, efficient asset management, and compliance with industry regulations. In this blog, we will discuss the features of ERP In the Oil And Gas Industry, the process of ERP Integration for the Oil and Gas Industry, and the types and costs of ERP software for Oil and Gas. Let’s get started:

What is Oil and Gas ERP Software?

An oil and gas ERP software streamlines finance, project management, manufacturing, and operations management. It effectively supports workforces and natural resources. The system integrates seamlessly with existing operations for efficiency and to minimize errors.

This helps identify supply chain issues early, prevents disturbances, and ensures operations run smoothly. Real-time responses allow for instant reactions to the challenges in the field or any supply chain challenges. Compliance needs are met by built-in tools that handle industry-specific regulations. Robust reporting features can provide actionable insights for better decision-making. For example, it can identify when equipment delivery has been delayed and suggest alternative suppliers right away.

Also Read: Top ERP Trends

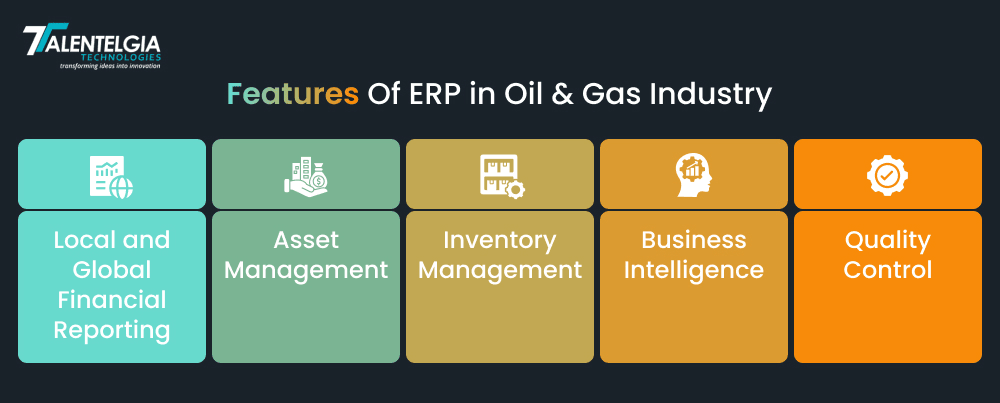

Features of ERP In the Oil And Gas Industry

The oil and gas industry is extremely dynamic and complex. ERP in the oil and gas industry delivers tailored solutions in finance, operations, and compliance. Let’s see what key features make an ERP system essential for this industry.

- Local and Global Financial Reporting

ERP systems in the oil and gas industry help streamline global and local financial reporting. Wells operate in one country, while refineries work in another. For instance, a refinery in Asia might serve customers in Europe, each following unique tax regulations. ERP helps generate location-specific reports while minimizing the company’s overall tax burden.

- Asset Management

ERP covers the effective handling of expensive oil and gas assets, such as offshore rigs or pipelines. Asset performance is accounted for to achieve constant value generation. For example, an ERP can schedule maintenance for a refinery such that costly downtimes do not occur. The Depreciation and amortization feature optimizes financial reporting for profit maximization.

- Inventory management

ERP deals with uncertain inventories specific to the oil and gas industry. For instance, geologists estimate the reserves, but actual quantities appear only after drilling. ERP accommodates these factors and adjusts with techniques such as fracking, which discovers new reserves. It equilibrates inventory to avoid overstocking or missed sales opportunities.

- Business Intelligence

ERP gives actionable business intelligence in the oil and gas industry. It carries analyses of world politics to predict shifts in supply and demand. For example, it tracks how geopolitical events affect the price of crude oil. Constant monitoring is also done by ERP for compliance with changing industry regulations.

- Quality Control

ERP systems improve quality control, ensuring products meet environmental and customer standards. They track losses during distribution to minimize waste and remain compliant. For example, ERP can identify and report liquid or gas losses in the refining process. It also ensures that customers receive customized products at the best possible costs.

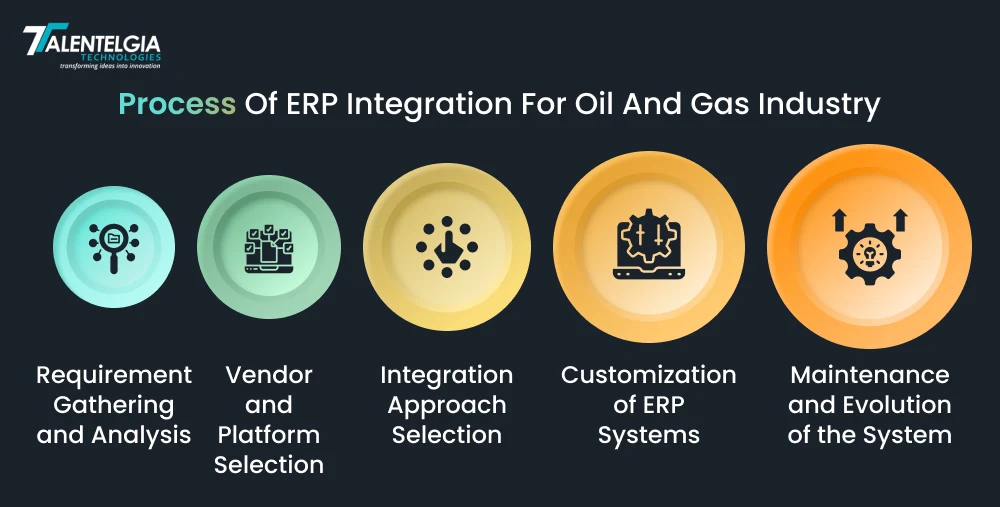

Process Of ERP Integration For Oil And Gas Industry

ERP software must integrate well with existing systems, IoT devices, and third-party platforms to maximize functionality. Migrating data, configuring the system, and training the users would all become part of the process of its successful implementation. Here’s how to undertake ERP integration in the oil and gas industry:

- Requirement Gathering and Analysis

The process starts by researching and engaging with the relevant stakeholders in discussions to understand what makes this organization unique. A firm experiencing delays in workflow, for instance, would realize the need to identify supply chain tracking inefficiencies. Analysis of these pain points ensures that the ERP system addresses regulatory demands and operational challenges effectively.

- Vendor and Platform Selection

The selection of the right ERP software is a very important business decision. Companies can build software from scratch for full customization or modify off-the-shelf solutions. For example, a small refinery may opt for a pre-built ERP for faster deployment, while larger operations might prefer a custom-built system for flexibility.

- Integration Approach Selection

Following the definition of requirements and selection of an ERP platform, the integration approach is chosen. Businesses can either integrate ERP systems in-house, hire freelancers, or outsource to experienced providers. For example, outsourcing ERP integration to experts in the Middle East usually results in better outcomes and faster implementation.

- Customization of ERP Systems

Customizing ERP software aligns it with specific organizational workflows. For instance, an oil and gas company might need modules for pipeline monitoring or predictive maintenance. Customization ensures that ERP systems meet unique needs, thus improving efficiency and compliance.

- Maintenance and Evolution of the System

Once deployed, ERP systems require periodic maintenance to remain secure and functional. For example, updating the system can correct bugs or enhance compatibility with IoT devices. Over time, businesses may integrate emerging technologies such as artificial intelligence or blockchain to further enhance ERP capabilities.

This structured approach ensures seamless ERP integration for oil and gas, optimizing operations and boosting overall performance.

Top 5 ERP Software For Oil And Gas

The oil and gas industry’s ERP selection must focus on flexibility, industry-specific features, and integration capabilities. It must also allow streamlining operations, enhancing visibility, and adherence to the strict norms of the industry. Below are the top five ERP options for the oil and gas industry:

- Odoo

Odoo is a perfect ERP for oil and gas because of its modularity and unmatched flexibility. Applications include financial management, supply chain, and project management. Its open-source platform allows for significant customization to specific industry needs. It simplifies operations and improves accessibility for all users through a user-friendly interface. Odoo has robust support, which makes it ideal for streamlining operations and meeting unique business requirements.

- Microsoft Dynamics 365

Microsoft Dynamics 365 integrates ERP and CRM functionalities in one platform. This enables proper functioning and management of finances in a singular package. It allows integration with the Microsoft product line, such as Office 365 and Azure, promoting productivity. The package assures clear data flow across various business functions.

- Infor CloudSuite

Infor CloudSuite is made specifically for the oil and gas industries. It has advanced features in asset management, regulatory compliance, and supply chain operations. The platform streamlines processes, enhances asset performance visibility and ensures regulatory adherence.

- IFS

IFS offers specialized ERP solutions for the oil and gas industry. It focuses on asset management, production optimization, and financial oversight. The platform provides detailed insights into asset performance, streamlines production processes, and ensures accurate financial reporting.

- Unit4 ERP

Unit4 ERP offers a versatile solution for managing finance, projects, and personnel in the oil and gas industry. Its user-friendly interface ensures ease of use. The system’s adaptability allows extensive customization to meet specific industry needs.

Quick Read: Which ERP System is The Best?

Cost To Integrate ERP For Oil And Gas Industry

The cost of integrating ERP for the oil and gas industry varies between $30,000 to $300,000 or more. It depends on the complexity of features, the tech stack, and the customization. The cost also depends on the number of integrations with existing systems and the location of ERP experts. In-house integration, outsourcing, or hiring freelancers also influence the overall cost.

Additional post-launch support and regular maintenance will cost an additional 15-20% per year. Below is a table outlining the costs and timelines of ERP integration:

| App Complexity | Average Cost | Average Timeline |

| Simple ERP with minimal integration (e.g., single module) | $30,000-$50,000 | 4-6 months |

| Medium complex ERP with multiple modules and moderate integration | $50,000-$120,000 | 4-9 months |

| Advanced ERP platform with complex integration and custom features | $120,000-$300,000 or more | 9 months to 1 year or more |

Conclusion

ERP software is changing the oil and gas industry by bringing about operational efficiency, better asset management, and compliance with industry standards. ERP development services will help overcome the challenges these companies experience when dealing with complex supply chains, changes in regulations, and market fluctuations. While certainly an expensive undertaking, integration of ERP software offers immense long-term benefits, including ease of process flows better decision making, and saving costs, thus serving as an asset to the businesses within this sector. Businesses will succeed in this industry and thrive amidst the ever-changing oil and gas industry with the right choice of ERP system and structured approach to integration.

Healthcare App Development Services

Healthcare App Development Services

Real Estate Web Development Services

Real Estate Web Development Services

E-Commerce App Development Services

E-Commerce App Development Services E-Commerce Web Development Services

E-Commerce Web Development Services Blockchain E-commerce Development Company

Blockchain E-commerce Development Company

Fintech App Development Services

Fintech App Development Services Fintech Web Development

Fintech Web Development Blockchain Fintech Development Company

Blockchain Fintech Development Company

E-Learning App Development Services

E-Learning App Development Services

Restaurant App Development Company

Restaurant App Development Company

Mobile Game Development Company

Mobile Game Development Company

Travel App Development Company

Travel App Development Company

Automotive Web Design

Automotive Web Design

AI Traffic Management System

AI Traffic Management System

AI Inventory Management Software

AI Inventory Management Software

AI Software Development

AI Software Development  AI Development Company

AI Development Company  AI App Development Services

AI App Development Services  ChatGPT integration services

ChatGPT integration services  AI Integration Services

AI Integration Services  Generative AI Development Services

Generative AI Development Services  Natural Language Processing Company

Natural Language Processing Company Machine Learning Development

Machine Learning Development  Machine learning consulting services

Machine learning consulting services  Blockchain Development

Blockchain Development  Blockchain Software Development

Blockchain Software Development  Smart Contract Development Company

Smart Contract Development Company  NFT Marketplace Development Services

NFT Marketplace Development Services  Asset Tokenization Company

Asset Tokenization Company DeFi Wallet Development Company

DeFi Wallet Development Company Mobile App Development

Mobile App Development  IOS App Development

IOS App Development  Android App Development

Android App Development  Cross-Platform App Development

Cross-Platform App Development  Augmented Reality (AR) App Development

Augmented Reality (AR) App Development  Virtual Reality (VR) App Development

Virtual Reality (VR) App Development  Web App Development

Web App Development  SaaS App Development

SaaS App Development Flutter

Flutter  React Native

React Native  Swift (IOS)

Swift (IOS)  Kotlin (Android)

Kotlin (Android)  Mean Stack Development

Mean Stack Development  AngularJS Development

AngularJS Development  MongoDB Development

MongoDB Development  Nodejs Development

Nodejs Development  Database Development

Database Development Ruby on Rails Development

Ruby on Rails Development Expressjs Development

Expressjs Development  Full Stack Development

Full Stack Development  Web Development Services

Web Development Services  Laravel Development

Laravel Development  LAMP Development

LAMP Development  Custom PHP Development

Custom PHP Development  .Net Development

.Net Development  User Experience Design Services

User Experience Design Services  User Interface Design Services

User Interface Design Services  Automated Testing

Automated Testing  Manual Testing

Manual Testing  Digital Marketing Services

Digital Marketing Services

Ride-Sharing And Taxi Services

Ride-Sharing And Taxi Services Food Delivery Services

Food Delivery Services Grocery Delivery Services

Grocery Delivery Services Transportation And Logistics

Transportation And Logistics Car Wash App

Car Wash App Home Services App

Home Services App ERP Development Services

ERP Development Services CMS Development Services

CMS Development Services LMS Development

LMS Development CRM Development

CRM Development DevOps Development Services

DevOps Development Services AI Business Solutions

AI Business Solutions AI Cloud Solutions

AI Cloud Solutions AI Chatbot Development

AI Chatbot Development API Development

API Development Blockchain Product Development

Blockchain Product Development Cryptocurrency Wallet Development

Cryptocurrency Wallet Development About Talentelgia

About Talentelgia  Our Team

Our Team  Our Culture

Our Culture

Healthcare App Development Services

Healthcare App Development Services Real Estate Web Development Services

Real Estate Web Development Services E-Commerce App Development Services

E-Commerce App Development Services E-Commerce Web Development Services

E-Commerce Web Development Services Blockchain E-commerce

Development Company

Blockchain E-commerce

Development Company Fintech App Development Services

Fintech App Development Services Finance Web Development

Finance Web Development Blockchain Fintech

Development Company

Blockchain Fintech

Development Company E-Learning App Development Services

E-Learning App Development Services Restaurant App Development Company

Restaurant App Development Company Mobile Game Development Company

Mobile Game Development Company Travel App Development Company

Travel App Development Company Automotive Web Design

Automotive Web Design AI Traffic Management System

AI Traffic Management System AI Inventory Management Software

AI Inventory Management Software AI Software Development

AI Software Development AI Development Company

AI Development Company ChatGPT integration services

ChatGPT integration services AI Integration Services

AI Integration Services Machine Learning Development

Machine Learning Development Machine learning consulting services

Machine learning consulting services Blockchain Development

Blockchain Development Blockchain Software Development

Blockchain Software Development Smart contract development company

Smart contract development company NFT marketplace development services

NFT marketplace development services IOS App Development

IOS App Development Android App Development

Android App Development Cross-Platform App Development

Cross-Platform App Development Augmented Reality (AR) App

Development

Augmented Reality (AR) App

Development Virtual Reality (VR) App Development

Virtual Reality (VR) App Development Web App Development

Web App Development Flutter

Flutter React

Native

React

Native Swift

(IOS)

Swift

(IOS) Kotlin (Android)

Kotlin (Android) MEAN Stack Development

MEAN Stack Development AngularJS Development

AngularJS Development MongoDB Development

MongoDB Development Nodejs Development

Nodejs Development Database development services

Database development services Ruby on Rails Development services

Ruby on Rails Development services Expressjs Development

Expressjs Development Full Stack Development

Full Stack Development Web Development Services

Web Development Services Laravel Development

Laravel Development LAMP

Development

LAMP

Development Custom PHP Development

Custom PHP Development User Experience Design Services

User Experience Design Services User Interface Design Services

User Interface Design Services Automated Testing

Automated Testing Manual

Testing

Manual

Testing About Talentelgia

About Talentelgia Our Team

Our Team Our Culture

Our Culture

Write us on:

Write us on:  Business queries:

Business queries:  HR:

HR: